1.Plant Situation

The Tỉnh Hà Nam protein powder factory in Vietnam has an annual output of 100,000 tons. The dust

floating in the factory is serious, endangering the health of workers.

2.Dangers of Floating Powder

Dangering workers' health, leading to increased wage demands to cope with adverse working conditions: Airborne powder can pose health risks to workers' respiratory systems, potentially causing respiratory illnesses with prolonged exposure. To cope with adverse working conditions and protect their health, workers may demand higher wages, which can raise the operating costs of the business.

Risk of powder explosions: When powder concentrations reach certain levels, there is a risk of dust explosions. Powder can form combustible mixtures in the air, which, if ignited, can lead to explosions causing severe casualties and property damage.

Significant material wastage: Powder dispersion can result in material wastage, affecting production efficiency and cost control. Accumulation of large amounts of powder can make materials difficult to recycle, increasing production costs for the enterprise.

Risk of material contamination: Powder may mix with raw materials during production, contaminating products and leading to decreased product quality. Contaminated products may trigger customer complaints and returns, further affecting the profitability and brand reputation of the enterprise.

In conclusion, powder floating poses threats to production equipment, worker health, and product quality. It also carries the risk of serious safety incidents. Therefore, businesses should implement effective dust control and management measures to ensure a safe production environment, protect employee health, maintain efficient production processes, and uphold product quality standards.

3.Solution of Henll Bulk Bag Vacuum Seal Machine

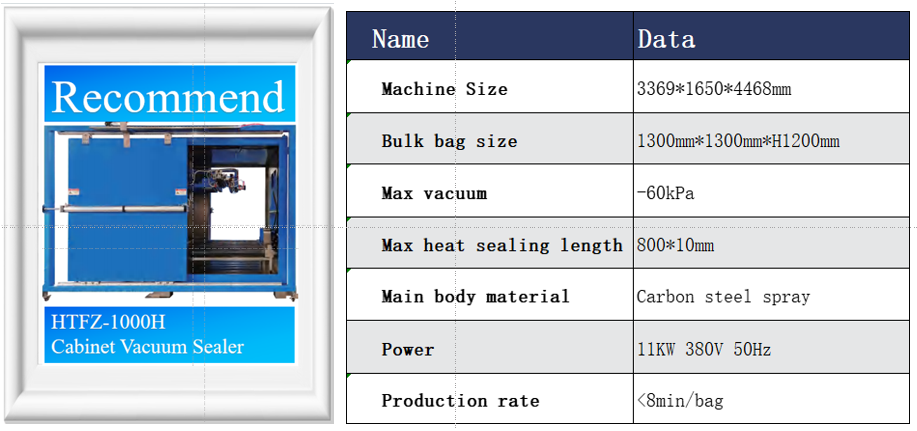

Henll Packaging Company has provided a scientific solution to address the aforementioned issues by introducing a vacuum filling machine for filling protein into bulk bags. Subsequently, a vacuum sealing machine is utilized to remove all air from the bags. This vacuum technology effectively eliminates dust on the factory's production line.

The process involves the following steps:

Vacuum Filling Machine: The vacuum filling machine is used to precisely fill protein into bulk bags. This machine ensures accurate filling without generating excess dust or powder dispersion.

Bulk Bag Sealing: After filling the bags with protein, a vacuum sealing machine is employed to seal the bags. This machine removes all air from the bags before sealing, preventing the escape of dust particles and maintaining a clean and dust-free environment.

By implementing this vacuum technology in the production process, plant can achieve the following benefits:

Dust-Free Production Line: The vacuum technology effectively removes dust and powder particles from the production line, creating a cleaner and healthier working environment for employees.

Improved Product Quality: By minimizing dust contamination, the quality of the packaged products is enhanced, reducing the risk of product defects and customer complaints.

Enhanced Worker Safety: Eliminating airborne dust particles contributes to a safer workplace, reducing the risk of respiratory health issues among workers.

Cost Savings: Reduced dust contamination leads to lower equipment maintenance costs, decreased material wastage, and improved overall operational efficiency.