Henll big bag vacuum sealer(HTFZ-50H) Technical Specification

Project | Classification |

| Equipment Dimensions | 3326*1930*2509mm |

| Bag Dimensions | 580*800mm Max |

| Max Heat Sealing Length | 600mm |

| Main Body Materia | SUS 304/316L |

| Production Rate | 1min/bag |

| Power | 2.75kw 380v 50hz |

| Weight | ≈300kg |

| Vacuum Degree | -70KPA |

What problems can the big bag vacuum sealer solve for you?

1

Issues related to product storage

Moisture and mold prevention

Extend Shelf Life

Prevent Contamination

Improve Storage Efficiency

Save Space

2

Addressing issues related to product transportation

Prevent Leakage and Contamination

Improve Transportation Efficiency

Prevent Moisture Ingress

Reduce Risk of Damage

3

Product sales issues

Enhance product appeal

Adapt to diverse market demands

Reduce return rates

Improve brand image

4

Solve problems in product production and processing

Increase production efficiency

Ensure product quality

Reduce waste

Improve working environment

Meet hygiene standards

Henll big bag vacuum sealer(HTFZ-50-5-10KG ) application scenarios

Widely used for materials that require vacuum extraction, such as powders and granular materials, including minerals, lithium iron phosphate, ternary materials, graphite powder, and other cathode and anode new energy materials, industrial building materials, grain, feed, and more. It is particularly suitable for situations where the material requires low gas content or when big bags(5-100KG) need to be stacked.

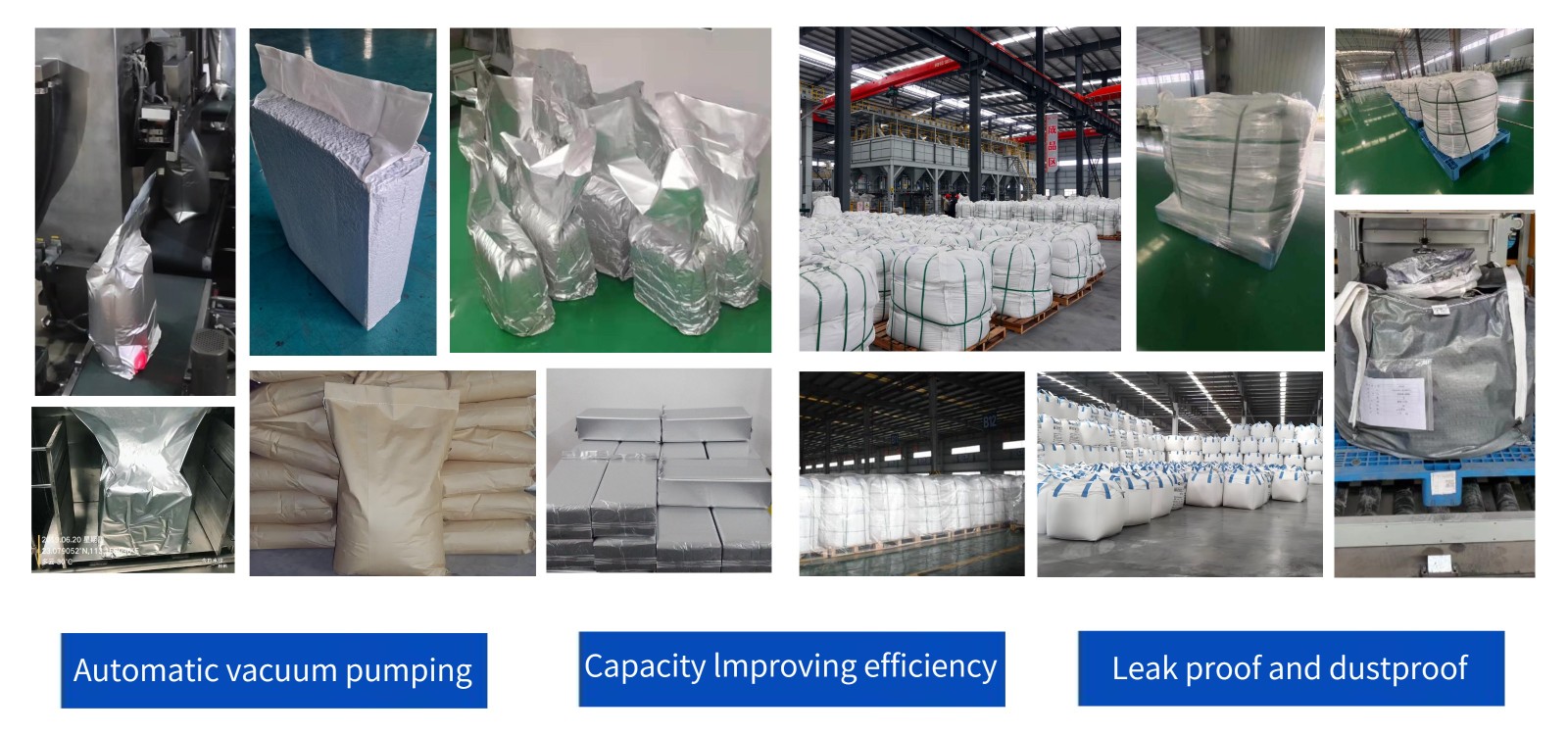

Henll big bag vacuum sealer packaging effect

Henll big bag vacuum sealer Some customers

Henll factory environment

The Henll factory building covers an area of 26,200 square meters; There are 17 CNC production centers;There are 2 laser equipment.;There are 73 senior technical engineers.

Big bag vacuum sealer F&Q

1.How effective is the sealing of the big bag vacuum sealing machine? Can it ensure a tight seal to prevent leaks and contamination?

Answer: The big bag vacuum sealing machine utilizes advanced vacuum sealing technology, ensuring a tight seal for every bag. Its efficient vacuuming and sealing process effectively prevents the intrusion of air, moisture, and microbes, thereby avoiding leaks and contamination during transportation and storage. This sealing effect not only protects the quality and safety of the products but also extends their shelf life, providing customers with a reliable packaging solution.

2. Is the operation of the equipment simple? Is professional training required to operate it?

Answer: The big bag vacuum sealing machine is designed with user-friendliness in mind, featuring an intuitive interface. Most devices come equipped with intelligent control systems and user-friendly interfaces, allowing operators to get started without complex professional training. Additionally, many manufacturers provide detailed operation manuals and video tutorials to help users quickly master the equipment's usage. For those who need a deeper understanding, some manufacturers also offer professional training services to ensure the correct and efficient use of the equipment.

3. Are the maintenance costs of this equipment high? What should be noted for daily maintenance?

Answer: The maintenance costs of the big bag vacuum sealing machine are relatively low. Due to its reasonable structural design and strong durability, the need for frequent repairs is reduced. Routine maintenance mainly includes regular cleaning of the device's surface and internal parts, checking the oil level of the vacuum pump, and replacing filters, among other simple operations. To ensure the long-term stable operation of the device, it is recommended that users perform regular inspections and maintenance according to the manufacturer's maintenance manual. This can not only extend the service life of the device but also keep it in good working condition.

4. What types of products is the big bag vacuum sealing machine suitable for packaging? Are there any special application limitations?

Answer: The big bag vacuum sealing machine is suitable for packaging various types of products, including but not limited to food, chemical products, pharmaceuticals, agricultural products, etc. Its powerful sealing capability and flexible adjustment functions allow it to meet the packaging needs of different industries and products. However, it is important to note that certain special products may require specific packaging materials or processes. Therefore, when selecting equipment, it is crucial to communicate in detail with the manufacturer to ensure that the chosen equipment meets the specific packaging requirements of the product. Additionally, special attention should be paid to safety precautions for flammable, explosive, toxic, or harmful products.

5. What after-sales services and support does the manufacturer provide after purchasing the big bag vacuum sealing machine?

Answer: After purchasing the big bag vacuum sealing machine, manufacturers typically offer comprehensive after-sales services and support. This includes installation and commissioning of equipment, operational training, maintenance, and technical consultation. Some manufacturers also provide remote monitoring and fault diagnosis services to promptly identify and resolve issues. Additionally, to ensure smooth usage of the equipment, manufacturers often provide a warranty service for a certain period, during which they will replace damaged parts free of charge. These after-sales services and support aim to provide customers with all-around protection, ensuring the long-term stable operation of the equipment and creating greater value for customers.