Plastic Granules Belt Magnetic Separator

Plastic Granules Belt Magnetic Separator Features

Efficient Removal of Magnetic Substances: The belt over magnetic machine is equipped with magnetic blocks made of high-strength permanent magnet materials, which can effectively adsorb and remove magnetic substances from the materials.

Automatic Separation Operation: The belt over magnetic machine is equipped with an automatic separation device, which can automatically separate the magnetic substances adsorbed on the magnetic blocks.

Flexible Adjustment and Adaptability: The magnetic intensity and working position of the belt over magnetic machine can be adjusted and set according to different materials and process requirements.

Reliable Safety: The design of the belt over magnetic machine takes into consideration safety issues. It is equipped with safety protection devices such as protective covers and safety switches to ensure the safety of operators.

Convenient Cleaning and Maintenance: The belt over magnetic machine is easy to clean and maintain. You only need to regularly remove the magnetic substances adsorbed on the magnetic blocks and perform necessary inspections and maintenance. The magnetic blocks are usually made of wear-resistant and corrosion-resistant materials, ensuring long-lasting durability.

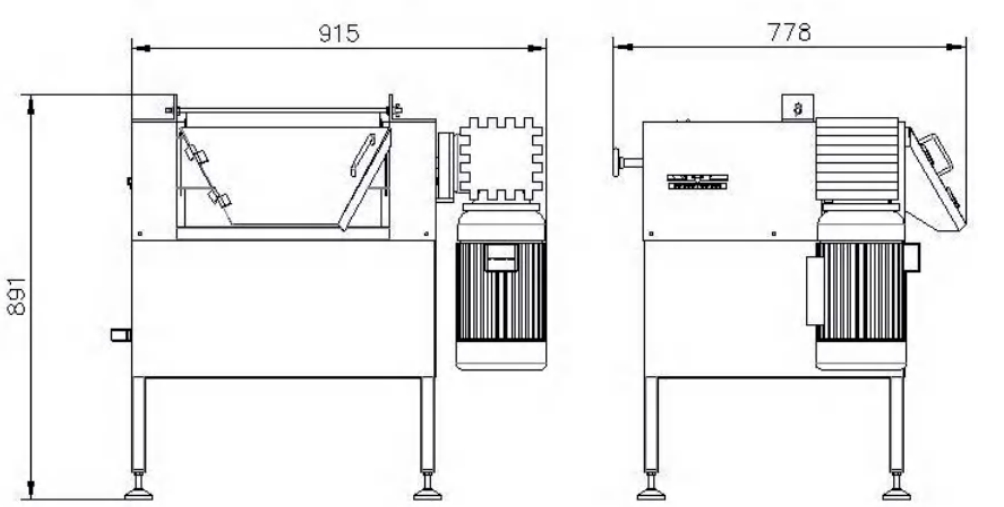

Plastic Granules Belt Magnetic Separator Specification

| project | Classification |

| Magnetic Material | lron content granule |

| Magnetic Conveyor Belt Material | PU & PVC |

| Magnetic Roll Material | Neodymium iron boron |

| Maximum Production Capacity | 2000kg/hour |

| Voltage | 380V |

| Magnetic Field Strength | 12000 Gauss |

| Required Power | 0.37kw |

| Machine Weight | Approximately 50kg |

Plastic Granules Belt Magnetic Separator Range Of Configuration

Food Industry: The belt over magnetic machine is crucial in the food industry. It can be used to remove metal impurities such as iron filings and iron chips from food raw materials. Whether it's flour, candy, grains, or meat processing, the belt over magnetic machine ensures food safety and quality.

Chemical Industry: In the chemical industry, the belt over magnetic machine is widely used in the processing of granular and powdered materials. It can remove metal impurities, preventing damage to equipment and production lines, while improving product quality and purity.

Mining Industry: In the mining industry, the belt over magnetic machine is used to remove ferromagnetic substances from ores and sands. This helps improve the quality of ores and sands while reducing wear on subsequent processing equipment.

Ceramic Industry: In the ceramic industry, the belt over magnetic machine is used to remove ferromagnetic impurities from ceramic raw materials, ensuring product quality and appearance. It can be applied in the production and processing of ceramic powders.

Metallurgical Industry: In the metallurgical industry, the belt over magnetic machine can be used to remove ferromagnetic substances from metal waste and slag. This helps improve the efficiency of waste recycling and reduces environmental pollution.

In addition to the above industries, the belt over magnetic machine is also widely used in waste disposal, papermaking, textile, pharmaceutical, and other industries. It helps remove metal impurities from materials, ensuring product quality and production efficiency.

If you have any questions or requirements regarding the application scope of the belt over magnetic machine, please feel free to contact us. Our sales team is dedicated to providing you with professional consultation and service.

Plastic Granules Belt Magnetic Separator Description

Transmission System: The belt over magnetic machine is equipped with a transmission system, including components such as a motor, gearbox, and belt.

Magnetic Separation Device: The magnetic separation device is the core part of the belt over magnetic machine, typically consisting of magnetic blocks and a magnetic separation drum.

Belt System: The belt over magnetic machine is equipped with a conveyor belt system, which transports materials from the feeding end to the magnetic separation drum.

Cleaning Device: The cleaning device of the belt over magnetic machine is used to remove the magnetic substances that are adsorbed on the magnetic blocks.

Control System: The belt over magnetic machine is equipped with an advanced control system, typically including a touchscreen interface and a PLC controller.