Plastic Granular And Powder Material Mixer

Plastic Granular And Powder Material Mixer FeaturesHigh-efficiency mixing ability: The offline premixer uses advanced mixing principles and designs to quickly and evenly mix materials (powders, granules) of different components.

Wide adaptability: The offline premixer has a wide adaptability, and the equipment design is flexible, which can be adjusted and set according to your needs to adapt to different mixing processes and requirements.

Precise control system: The offline premixer uses an advanced control system to improve the accuracy and consistency of mixing.

Reliable safety: The offline premixer has reliable safety and can stop in time in emergency situations to protect the safety of operators and equipment.

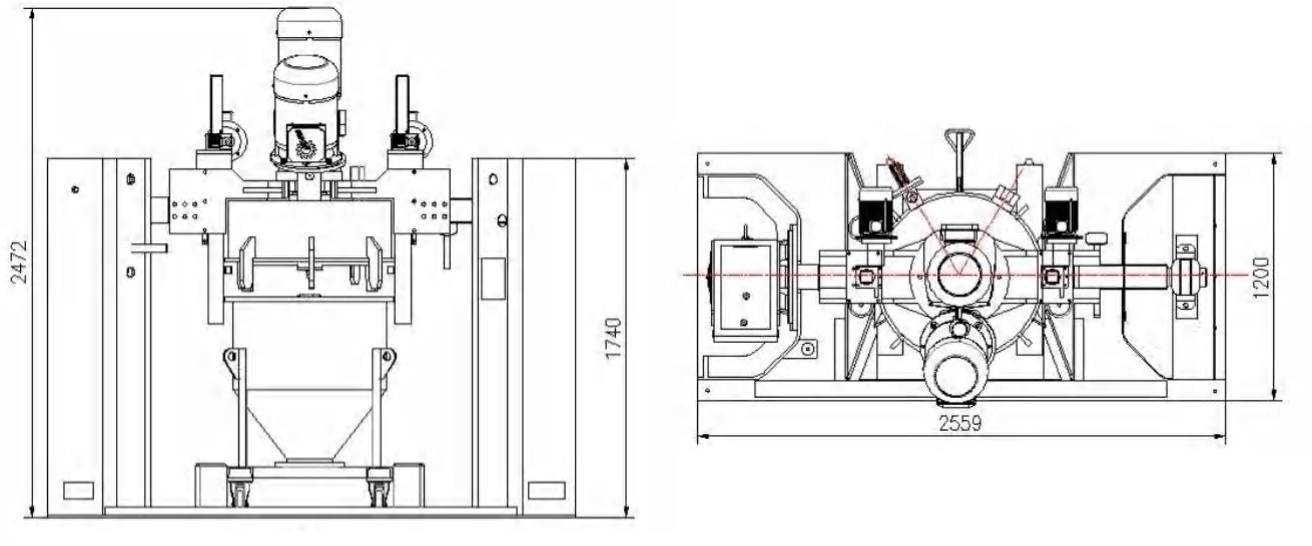

Plastic Granular And Powder Material Mixer Specification

| project | classification |

| Filling method: | 1 shot/1 bucket filled |

| Mixed materials: | Powder |

| Impeller material: | SUS304 |

| Maximum mixing capacity: | 5 batches per hour |

| Filing volume: | 300 liters per time |

| Maximum air consumption (5kg/Gcm?): | 0.5Nm3/min |

| Required power: | 30kg |

| Machine weight: | Approximately 3000 kg |

Plastic Granular And Powder Material Mixer Configuration

Food Industry: Offline pre-mixers are widely used in the food industry for blending various food ingredients. Whether it's powders, granules, or liquids, offline pre-mixers can achieve fast and uniform mixing of materials such as flour, seasonings, additives, and more.

Chemical Industry: Offline pre-mixers also find extensive applications in the chemical industry. They are used for blending various chemical raw materials such as pigments, dyes, rubber additives, plastic materials, and more. The efficient mixing capability of offline pre-mixers ensures the quality and consistency of the mixtures.

Pharmaceutical Industry: Offline pre-mixers play a vital role in the pharmaceutical industry. They are used for blending pharmaceutical raw materials, excipients, and various additives during the pharmaceutical manufacturing process. The efficient mixing and uniformity of offline pre-mixers ensure the quality and effectiveness of medications.

Agricultural Industry: In the agricultural industry, offline pre-mixers are used for blending feed ingredients such as grains, soybean meal, fish meal, and more. They ensure the uniform distribution of various components in the feed, improving its quality and nutritional value.

Other Industries: Offline pre-mixers are also applied in many other industries such as personal care, environmental protection, construction materials, and more. They can be used for blending various materials like detergents, paints, coatings, cement, and more.

Plastic Granular And Powder Material Mixer Description

Mixing Drum: The core component of the offline pre-mixer is the mixing drum, which is typically made of stainless steel or carbon steel. The mixing drum has sufficient capacity to accommodate the materials to be mixed. It is designed with special internal features to ensure thorough and uniform mixing of the materials.

Mixing Blades or Agitators: The mixing drum is equipped with high-speed rotating mixing blades or agitators. These blades or agitators are responsible for dispersing and breaking down the materials and blending them with other components. The number and shape of the mixing blades or agitators can be designed based on the materials and process requirements.

Motion Transmission System: The offline pre-mixer is equipped with a motion transmission system to drive the rotation of the mixing blades or agitators. This is typically achieved through a combination of a motor, gearbox, and transmission devices. The motion transmission system allows for adjusting the speed and motion mode as needed to achieve optimal mixing effects.

Control System: The offline pre-mixer is equipped with an advanced control system, typically including a touchscreen interface and a PLC controller. Operators can set and adjust parameters through the touchscreen interface for automated control and monitoring. The control system can also record and display key data of the mixing process for quality control and process optimization purposes.

Safety Devices: The offline pre-mixer is equipped with various safety devices to ensure the safety of operators and the equipment. These safety devices include protective shields, emergency stop buttons, and electrical protection devices. In case of emergencies, these devices can promptly stop the operation to protect the safety of personnel and equipment.