1.Using

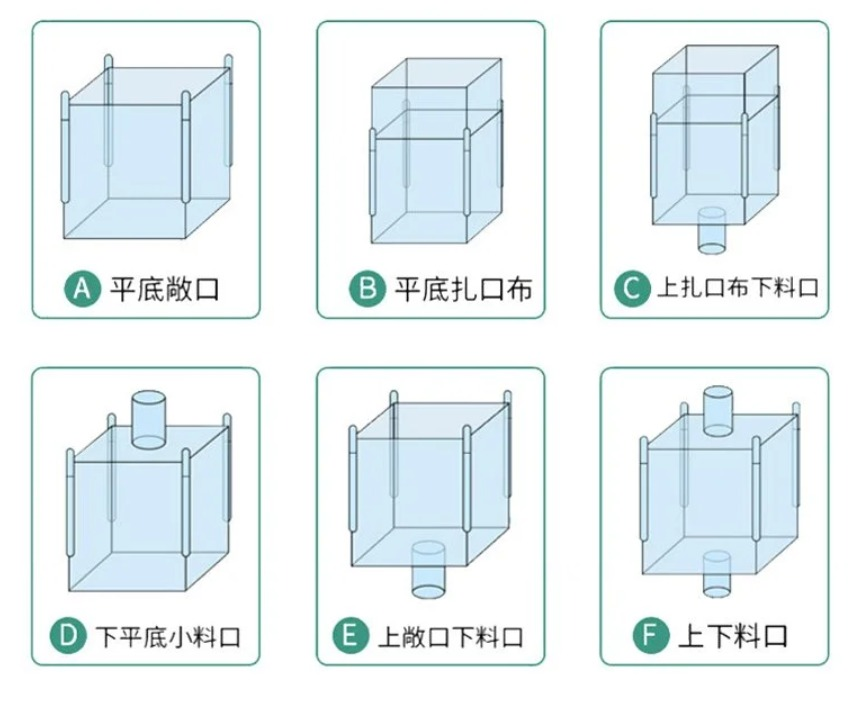

In the chemical industry, powdered products are commonly exported using bulk bags (also known as FIBCs - Flexible Intermediate Bulk Containers). Here is an overview of the typical scenario when chemical powders are exported using bulk bags:

Packaging Form: Chemical powders are usually transported in bulk form, and using bulk bags allows for efficient packaging and transportation of large quantities of powder products.

Standardization Requirements: Exported powder products typically need to comply with international transportation and packaging standards. Bulk bags, as a standardized packaging form, meet these requirements.

Convenience in Transport: Bulk bags are convenient for loading, unloading, and stacking, enhancing transportation efficiency, reducing manual handling, and minimizing losses.

Product Quality Protection: Bulk bags are often made from special materials that are moisture-resistant and dust-proof, effectively safeguarding powder products from external influences like moisture and dust, ensuring product quality.

Pollution Reduction: Bulk bag packaging can decrease powder spillage and pollution during loading and unloading, helping to maintain a clean environment.

Cost Considerations: Bulk bag packaging may be more cost-effective compared to other forms of packaging (such as drums), especially for large-scale exports.

Overall, using bulk bags for exporting chemical powders offers advantages in terms of convenience, standardization, product quality protection, environmental preservation, and cost-effectiveness, making it a common choice for export packaging in the chemical industry.

2.Advantages

Using vacuum sealing for chemical powder packaging offers several advantages:

Isolation from Air and Moisture to Prevent Degradation:

Vacuum sealing effectively isolates the packaged chemical powder from air and moisture. This airtight environment helps prevent oxidation, moisture absorption, and other forms of degradation that could compromise the quality and integrity of the powder over time. By sealing out these damaging elements, the shelf life and quality of the powder can be significantly extended.

Convenient Transportation:

Vacuum-sealed chemical powder packaging is typically more compact and stable. This compactness makes the packages easier to handle, stack, and transport. The reduced volume due to vacuum sealing can also lead to more efficient use of storage space and streamlined logistics during transportation, reducing the risk of spills or damage during transit.

Reduced Gas Content:

Vacuum sealing helps reduce the gas content within the packaging. Chemical powders with high air content can experience issues like clumping, caking, or uneven filling within the packaging. By removing excess air through vacuum sealing, the powder remains loose and free-flowing, ensuring consistent product quality and easier handling during various stages of transportation and use.