1.Fibc bag

FIBC’s are one of the most cost effective and ideal types of packaging for handling, shipping, and storing dry bulk products for weights up to 5000 Lbs.

Description

The fabric of the ventilated bag design maximizes airflow and reduces product spoilage due to moisture and mold build-up.

Features

Ventilated bags are is produced using woven polypropylene, netting, or a combination of both. It is an effective method of packing and shipping large quantity bulk goods such as potatoes and onions safely, without product damage.

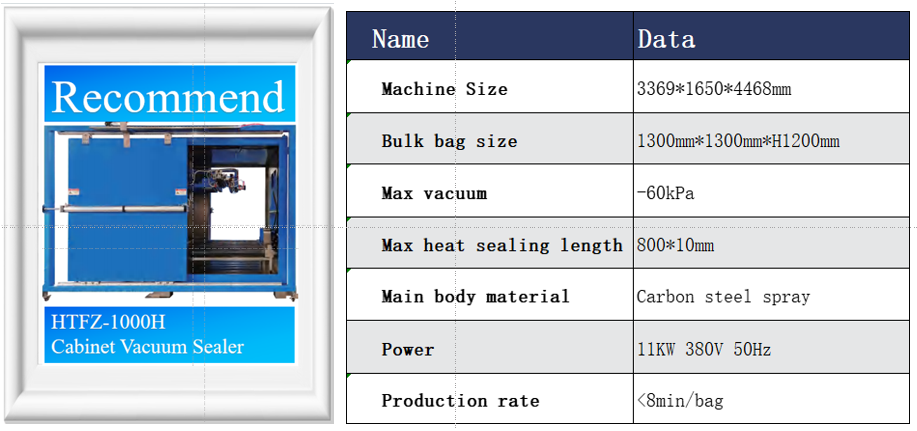

2.Vacuum sealer for fibc bag

Vacuum sealing bulk bags offers several advantages:

Isolation from Air:

Vacuum sealing bulk bags effectively isolates the contents from air. This airtight environment helps prevent oxidation and degradation of the materials inside, preserving their quality and extending their shelf life.

Pollution Isolation:

Vacuum sealing provides a barrier against external pollutants and contaminants, safeguarding the contents of the bulk bags from contamination. This is particularly crucial for sensitive materials or products that can be easily affected by environmental factors.

Reduced Volume:

Vacuum sealing compresses the contents of the bulk bags, reducing their volume. This reduction in size helps optimize storage space, making transportation and storage more efficient and cost-effective.

Convenient for Ocean Shipping and Container Loading:

Vacuum-sealed bulk bags are more compact and stable, making them easier to handle and stack inside shipping containers. This convenience in packing and loading facilitates smoother logistics for ocean shipping, ensuring that the bags are securely stored and transported.

Reduction of Internal Material Friction:

Vacuum sealing helps to eliminate excess air within the bulk bags, reducing the movement and shifting of materials inside. This minimizes friction between the materials, preventing damage or alteration of the contents during transportation and handling.