Full-Automatic Industrial Particle Filling And Packaging Machine

Efficiency: The fully automatic industrial particle filling and packaging machine utilizes advanced automation technology to achieve high-speed and continuous packaging operations.

Precision: Equipped with precision measuring devices, the fully automatic industrial particle filling and packaging machine can accurately measure and control the weight of granular products.

Versatility: The fully automatic industrial particle filling and packaging machine has flexible packaging capabilities, suitable for various granular products such as food, chemicals, and pesticides.

Reliability: Manufactured with high-quality materials and components, fully automatic industrial particle filling and packaging machine ensures stable performance and reliable operation.

Ease of use: Designed with simplicity in mind, fully automatic industrial particle filling and packaging machine is easy to operate and maintain.

Hygiene: Ensuring that granular products are not contaminated or exposed to moisture during the packaging process.

Automation control: fully automatic industrial particle filling and packaging machine is equipped with advanced automation control systems, enabling automatic operation and monitoring of the entire packaging process.

Full-Automatic Industrial Particle Filling And Packaging Machine Specification

| Project | Classification | |

| Filling method | 1 release/1 bag | 1 release/1 bag |

| Packaging material | granules | granules |

| Bag material | a.Coated kraft paper bags b.Laminated woven bags | a.Coated kraft paper bags b.Laminated woven bags |

| Maximum packaging capacity | 140 bags/hour | 140 bags/hour |

| Filling volume | 15-25 kg/bag | 15-25 kg/bag |

| Bag size: Length (mm) | Paper bags 750-950 Woven bags 550-1050 | Paper bags 750-950 |

| Bag size: Width (mm) | 400-520 | 380-460 |

| Bag size: Bottom width (mm) | Paper bag 75 | ----- |

| Sealing method | Paper bags: linear sewing, folding sewing, border sewing, heat sealing. | |

| Maximum air consumption (5kg/Gcm³) | 0.5Nm³/min | 0.5Nm³/min |

| Required power | 2kw | 3kw |

| Machine weight | Approximately 1000 kg | Approximately 1000 kg |

Full-Automatic Industrial Particle Filling And Packaging Machine Description

In the food industry, the fully automatic industrial granule packaging machine is used for packaging coffee beans, nuts, puffed snacks, candies, dried fruits, and more.

In the chemical industry, it is utilized for packaging fertilizers, pigments, plastic granules, cosmetics, and other products.

In the pesticide industry, it is employed for packaging granular pesticide products.

In the pharmaceutical industry, it is used for packaging granular medicines and health supplements.

In the personal care industry, it is utilized for packaging granular detergents, laundry powders, and other products.

In other industries, it is employed for packaging granular pet food, building materials, electronic components, mineral products, and more.

Full-Automatic Industrial Particle Filling And Packaging MachineConstruction

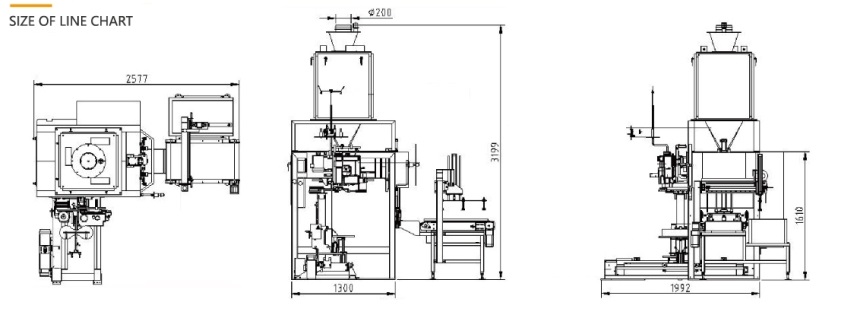

The Henll The fully automatic industrial particle filling and packaging machine is composed of several key components that work together to complete the packaging process of granular products, improving packaging efficiency and product quality. These components include the automatic bagging system, feeding system, measuring system, packaging bag conveying system, sealing system, control system, and conveying system. Through their close coordination, these components ensure a smooth and efficient packaging process for granular products.