For the export 500kg bulk bag vacuum sealing machine, the advantages are as follows:

1.Advantage

Preservation of Material Freshness, Ensuring Product Quality: Through vacuum sealing, the bulk bag effectively removes oxygen, slowing down the oxidation process and preventing material spoilage. This method helps maintain the freshness and quality of products, especially for long-term storage or export purposes.

Convenient for Handling, Disassembly, Stacking, and Storage: Vacuum-sealed bulk bags are more compact and stable, making them easy to transport and stack. Additionally, this sealing method makes the bags easier to disassemble and load, improving operational convenience and efficiency, which is beneficial for warehouse management.

Prevention of Contamination, Air, and Moisture Isolation: The vacuum sealing machine eliminates air and moisture from within the bulk bag, creating a sealed environment that effectively isolates the product from external contaminants. This approach not only helps maintain product hygiene and quality but also reduces factors that could lead to product deterioration.

2.Note

When using the bulk bag vacuum sealing machine, three key points to consider are:

Requirement for an Air Compressor: To operate effectively, the bulk bag vacuum sealing machine requires an air compressor to create the necessary vacuum pressure for sealing the bags. The air compressor generates the negative pressure essential for the vacuum sealing process. Ensuring a properly functioning and adequately sized air compressor is crucial for the machine's performance.

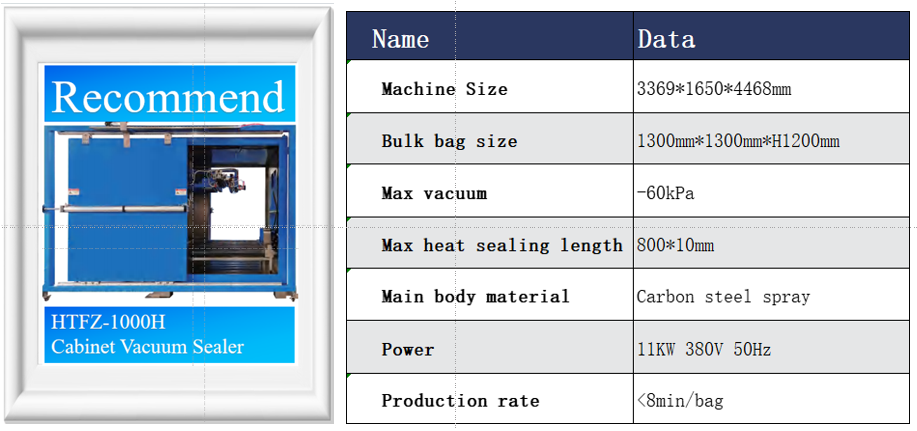

Adequate Factory Space and Ceiling Height: The machine's installation requires sufficient factory space and ceiling height to accommodate its size and operation. A spacious area allows for the machine to be set up and operated comfortably, ensuring ease of access for maintenance and operation. Sufficient ceiling height is necessary to accommodate the machine's vertical components and ensure smooth operation without any obstructions.

Regular Cleaning of the Vacuum Chamber: The vacuum chamber of the machine needs to be cleaned regularly to maintain optimal performance. Accumulation of dust, debris, or residues in the vacuum chamber can impact the sealing quality and efficiency of the machine. Regular cleaning helps prevent contamination and ensures consistent and reliable vacuum sealing of the bulk bag

In conclusion, an export-oriented bulk bag vacuum sealing machine offers an efficient and reliable solution for packaging and transporting materials for export. It ensures product quality and safety throughout the export process through the preservation of freshness, ease of handling, and contamination prevention features.